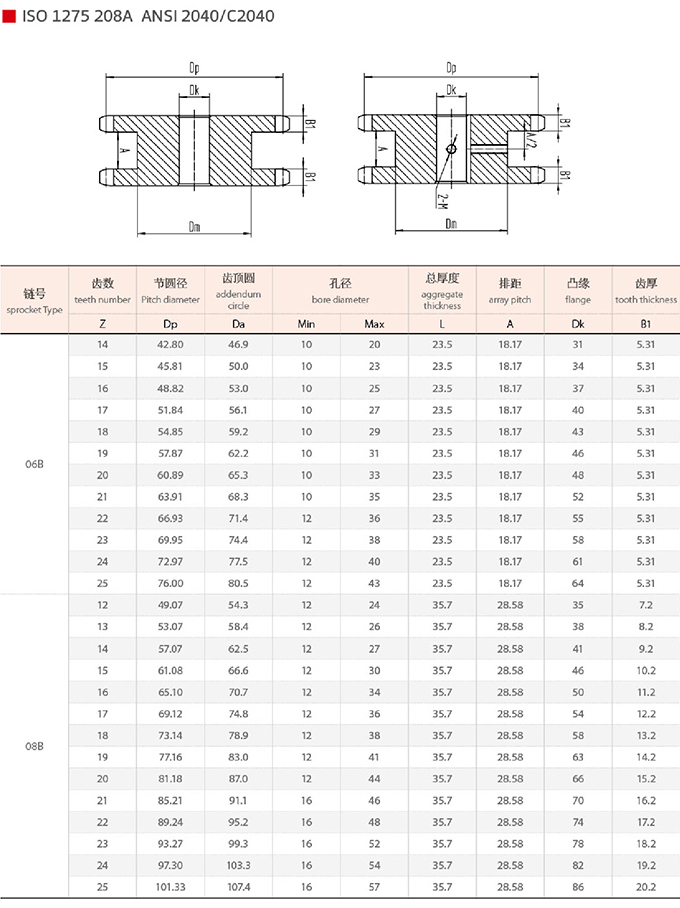

Double Drive Sprocket

1. Use imported CNC lathe to complete the processing of clamping hole, roughness can reach accuracy of precision gear.

2. Use high quality 45# carbon structural steel to form by forging.Stream line is complete, sprocket’s life improved 15% than machining.

3. Combine with the actual production precision of the chain, improve 50% service life of chains and sprockets.

4. Use high precision gear hobbing machine for gear hobbing can ensure accurate pitch,same tooth form,low runout,mesh correctly.

5. High-frequency Quenching Process

6. Use ternary surface strengthening treatment technology,delete the stess and generate presure stress,improve wearing resistance by 20%.

Reviews

There are no reviews yet.