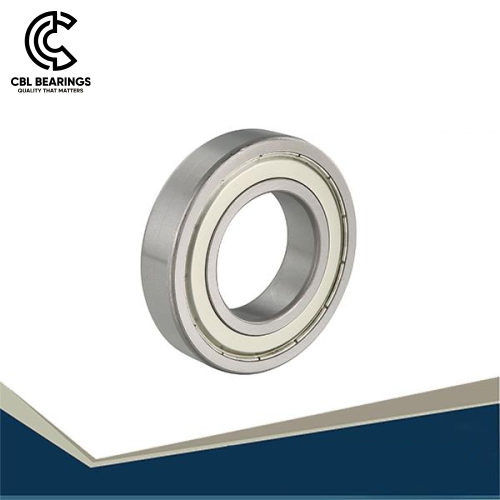

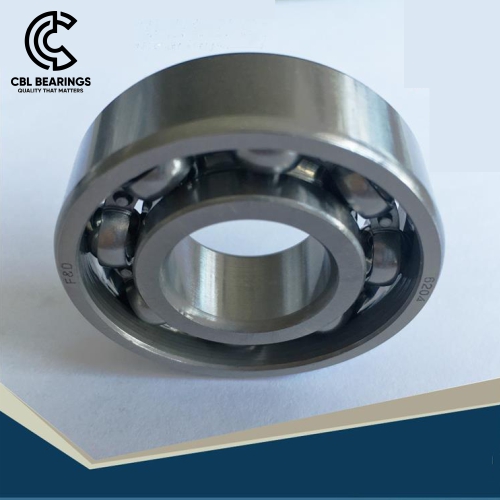

High Precision Ball Roller Joint Bearings For 6000, 6200, 6300 Series For Auto Parts

High Precision FD Ball Roller Bearings for 6000, 6200, 6300 Series for Auto Parts

Description

Product Description

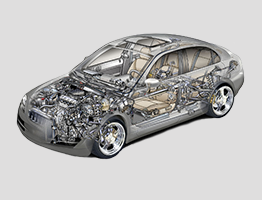

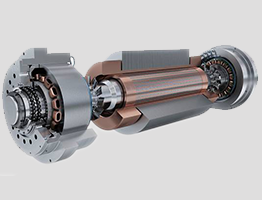

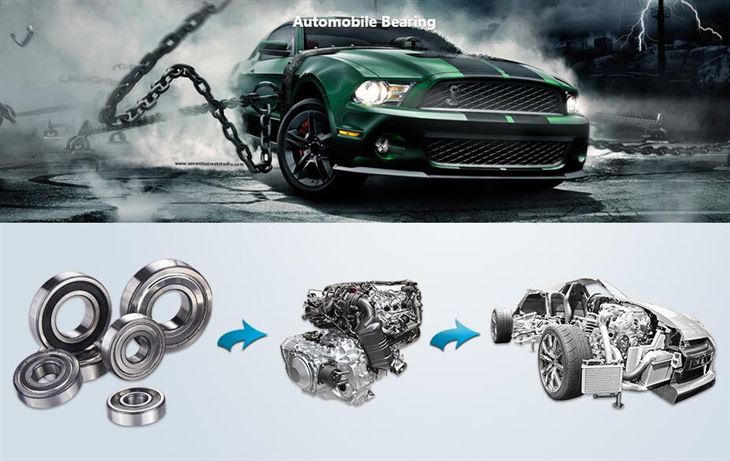

Deep groove ball bearings mainly take radial load as well as take moderate axial load. With less coefficient of friction, high limiting speed, large size range and variations of structure, they are suitable for precision instruments, low noise motors, automobiles, motorcycles, and other common machinery, as a widely used type of bearings in machinery industry.

Features:

1. Low density. As the rolling body density decreases, high-speed operation of its centrifugal load is also reduced, which can work at a higher speed.

2. Moderate elastic modulus. Elastic modulus is too large due to stress concentration and reduces the bearing capacity of the bushing.

3. The thermal expansion coefficient is small. Reduce the sensitivity to temperature changes, so that the bearing operating temperature range is wider.

4. High compressive strength. High compressive strength is the need for high stress for rolling bearings. 5. High hardness and high toughness. These two properties combine to achieve better surface roughness; and can prevent external particles and shock damage.

6. Good anti-rolling contact fatigue and has a peel failure mode.

7. Special occasions should have high temperatures, corrosion resistance and stability.

Applications:

The ceramic material has low density, medium elastic modulus, thermal expansion coefficient is small, high hardness, high temperature, corrosion resistance, non-magnetic, etc., to silicon nitride ceramic ball for the rolling body of ceramic ball bearings can significantly improve the bearing contact fatigue life, Has greatly expanded the application of rolling bearings, has been widely used in a variety of high-precision, high-speed machine tools, automobiles, racing, subway, motor, aero engine, petrochemical machinery, metallurgical machinery and other fields.

| Bearing No. | Boundary Dimensions(mm) | Basic Load Rating (KN) | Weight | |||||||

| Open | Shields | Seals | d | D | B | Cr. | Cor. | (Kg) | ||

| 6000 | 6000-Z | 6000-2Z | 6000-RS | 6000-2RS | 10 | 26 | 8 | 4.58 | 1.98 | 0.02 |

| 6001 | 6001-Z | 6001-2Z | 6001-RS | 6001-2RS | 12 | 28 | 8 | 5.1 | 2.36 | 0.02 |

| 6002 | 6002-Z | 6002-2Z | 6002-RS | 6002-2RS | 15 | 32 | 9 | 5.6 | 2.85 | 0.033 |

| 6003 | 6003-Z | 6003-2Z | 6003-RS | 6003-2RS | 17 | 35 | 10 | 6 | 3.25 | 0.04 |

| 6004 | 6004-Z | 6004-2Z | 6004-RS | 6004-2RS | 20 | 42 | 12 | 9.4 | 5 | 0.07 |

| 6005 | 6005-Z | 6005-2Z | 6005-RS | 6005-2RS | 25 | 47 | 12 | 10 | 5.85 | 0.083 |

| 6006 | 6006-Z | 6006-2Z | 6006-RS | 6006-2RS | 30 | 55 | 13 | 12.7 | 8 | 0.126 |

| 6007 | 6007-Z | 6007-2Z | 6007-RS | 6007-2RS | 35 | 62 | 14 | 16 | 10.2 | 0.163 |

| 6008 | 6008-Z | 6008-2Z | 6008-RS | 6008-2RS | 40 | 68 | 15 | 16.6 | 11.6 | 0.2 |

| 6009 | 6009-Z | 6009-2Z | 6009-RS | 6009-2RS | 45 | 75 | 16 | 20 | 14.3 | 0.253 |

| 6010 | 6010-Z | 6010-2Z | 6010-RS | 6010-2RS | 50 | 80 | 16 | 20.8 | 15.6 | 0.282 |

| 6011 | 6011-Z | 6011-2Z | 6011-RS | 6011-2RS | 55 | 90 | 18 | 28.5 | 21.2 | 0.409 |

| 6012 | 6012-Z | 6012-2Z | 6012-RS | 6012-2RS | 60 | 95 | 18 | 29 | 23.2 | 0.413 |

| 6013 | 6013-Z | 6013-2Z | 6013-RS | 6013-2RS | 65 | 100 | 18 | 30.5 | 25 | 0.464 |

| 6014 | 6014-Z | 6014-2Z | 6014-RS | 6014-2RS | 70 | 110 | 20 | 38 | 31 | 0.642 |

| 6201 | 6201-Z | 6201-2Z | 6201-RS | 6201-2RS | 12 | 32 | 10 | 6.8 | 3.05 | 0.039 |

| 6202 | 6202-Z | 6202-2Z | 6202-RS | 6202-2RS | 15 | 35 | 11 | 7.8 | 3.75 | 0.045 |

| 6203 | 6203-Z | 6203-2Z | 6203-RS | 6203-2RS | 17 | 40 | 12 | 9.58 | 4.78 | 0.064 |

| 6204 | 6204-Z | 6204-2Z | 6204-RS | 6204-2RS | 20 | 47 | 14 | 12.7 | 6.55 | 0.11 |

| 6205 | 6205-Z | 6205-2Z | 6205-RS | 6205-2RS | 25 | 52 | 15 | 14 | 7.8 | 0.133 |

| 6206 | 6206-Z | 6206-2Z | 6206-RS | 6206-2RS | 30 | 62 | 16 | 19.3 | 11.2 | 0.201 |

| 6207 | 6207-Z | 6207-2Z | 6207-RS | 6207-2RS | 35 | 72 | 17 | 25.5 | 15.3 | 0.299 |

| 6208 | 6208-Z | 6208-2Z | 6208-RS | 6208-2RS | 40 | 80 | 18 | 29 | 18 | 0.382 |

| 6209 | 6209-Z | 6209-2Z | 6209-RS | 6209-2RS | 45 | 85 | 19 | 31 | 20.4 | 0.407 |

| 6210 | 6210-Z | 6210-2Z | 6210-RS | 6210-2RS | 50 | 90 | 20 | 36.5 | 24 | 0.478 |

| 6211 | 6211-Z | 6211-2Z | 6211-RS | 6211-2RS | 55 | 100 | 21 | 43 | 29 | 0.632 |

| 6212 | 6212-Z | 6212-2Z | 6212-RS | 6212-2RS | 60 | 110 | 22 | 52 | 36 | 0.807 |

| 6213 | 6213-Z | 6213-2Z | 6213-RS | 6213-2RS | 65 | 120 | 23 | 60 | 41.5 | 1.03 |

| 6214 | 6214-Z | 6214-2Z | 6214-RS | 6214-2RS | 70 | 125 | 24 | 62 | 44 | 1.11 |

| 6215 | 6215-Z | 6215-2Z | 6215-RS | 6215-2RS | 75 | 130 | 25 | 66 | 49.5 | 1.7 |

| 6216 | 6216-Z | 6216-2Z | 6216-RS | 6216-2RS | 80 | 140 | 28 | 72.5 | 53 | 2.1 |

| 6217 | 6217-Z | 6217-2Z | 6217-RS | 6217-2RS | 85 | 150 | 28 | 84 | 62 | 2.1 |

| 6218 | 6218-2Z | 6218-2RS | 90 | 160 | 30 | 96.5 | 72 | 2.26 | ||

| 6300 | 6300-Z | 6300-2Z | 6300-RS | 6300-2RS | 10 | 35 | 11 | 8.15 | 3.45 | 0.057 |

| 6301 | 6301-Z | 6301-2Z | 6301-RS | 6301-2RS | 12 | 37 | 12 | 9.65 | 4.15 | 0.064 |

| 6302 | 6302-Z | 6302-2Z | 6302-RS | 6302-2RS | 15 | 42 | 13 | 11.4 | 5.4 | 0.09 |

| 6303 | 6303-Z | 6303-2Z | 6303-RS | 6303-2RS | 17 | 47 | 14 | 13.4 | 6.55 | 0.117 |

| 6304 | 6304-Z | 6304-2Z | 6304-RS | 6304-2RS | 20 | 52 | 15 | 15.8 | 7.8 | 0.155 |

| 6305 | 6305-Z | 6305-2Z | 6305-RS | 6305-2RS | 25 | 62 | 17 | 22.4 | 11.4 | 0.24 |

| 6306 | 6306-Z | 6306-2Z | 6306-RS | 6306-2RS | 30 | 72 | 19 | 26.5 | 16.3 | 0.363 |

| 6307 | 6307-Z | 6307-2Z | 6307-RS | 6307-2RS | 35 | 80 | 21 | 33.5 | 19 | 0.481 |

| 6308 | 6308-Z | 6308-2Z | 6308-RS | 6308-2RS | 40 | 90 | 23 | 42.5 | 25 | 0.654 |

| 6309 | 6309-Z | 6309-2Z | 6309-RS | 6309-2RS | 45 | 100 | 25 | 53 | 31.5 | 0.869 |

| 6310 | 6310-Z | 6310-2Z | 6310-RS | 6310-2RS | 50 | 110 | 27 | 61.8 | 38 | 1.12 |

| 6311 | 6311-Z | 6311-2Z | 6311-RS | 6311-2RS | 55 | 120 | 29 | 71.5 | 47.5 | 1.43 |

| 6312 | 6312-Z | 6312-2Z | 6312-RS | 6312-2RS | 60 | 130 | 31 | 82 | 52 | 1.79 |

| 6313 | 6313-Z | 6313-2Z | 6313-RS | 6313-2RS | 65 | 140 | 33 | 92.5 | 59.5 | 2.08 |

| 6314 | 6314-Z | 6314-2Z | 6314-RS | 6314-2RS | 70 | 150 | 35 | 104 | 68 | 2.52 |

| 6315 | 6315-Z | 6315-2Z | 6315-RS | 6315-2RS | 75 | 160 | 37 | 113 | 77 | 3.02 |

| 6316 | 6316-Z | 6316-2Z | 6316-RS | 6316-2RS | 80 | 170 | 39 | 123 | 86.5 | 3.59 |

Why Chooes Us?

Reviews

There are no reviews yet.