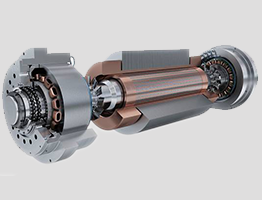

Side Bow Chains

1. O/X-ring seals the outlet of lubrication oil

2. Sintered Bushing. special sintered material, which can meet the customers’ demand for free oiling and long service life

3. α-PIN. Anti-wearing、Anti-high tempreture、Anti-corruption

4. Solid Bush. using cold extrusion technology to shape, seamless cylinder, roundness greatly improved, not easy to deformation.

5. Strong Pre-tensioning. improve anti-fatigue strength.

6. Shot Blasting. Can significantly improve the apparent fatigue life and prevent the microcracks in the chain plates.

7. Vacuum Oiling. each aperture of parts is filled with wear-resistant grease and the chain life is extended by 30%

Description

Application area:

- Material Handing Equipment

Product presentation:

-

- The side bending chain has a certain flexibility margin between the pin shaft and the sleeve, and between the outer chain plate and the inner chain plate. This provides an extra radius for side bends, and its basic dimensions are the same as standard roller chains. By applying various accessories to the chain, it can also be used as a precision conveyor chain. Zhenghe currently provides side bend chains with a side bend radius of 350-500mm.

Reviews

There are no reviews yet.