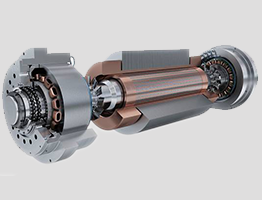

Radial spherical plain bearings incorporate two distinct structural elements:

- Inner ring with a spherical, convex outside surface

- Outer ring with a spherical, concave inside surface

The complementary curvatures make them well-suited for bearing arrangements where alignment movements between the shaft and housing must be accommodated, as well as where oscillating or recurrent tilting or slewing movements occur at slow, sliding speeds.

The bearings are available in two major variations: spherical plain bearings requiring maintenance (steel-on-steel) and maintenance-free spherical bearings. The former requires regular lubrication and is suitable for heavy loads moving in alternating direction; and the latter has low friction and is used for applications where long bearing life is required or where operating conditions make steel-on-steel bearings impractical.

Maintenance for both differs and reflects their composition. For maintenance-type spherical plain bearings, some bearing designs can be fitted with seals to repel contamination, while multiple split outer rings can be fitted with retaining rings. Spacers and extended inner rings can also be incorporated.

For maintenance-free type spherical plain bearings, carbon steel outer rings can be pressed around the inner ring, or it can have radial splits that are held together by screws. Some designs can be fitted with seals that keep out contaminants. Some can also be fitted with retaining rings.

An important note for either concerns operating temperature range. Steel-on-steel, steel-on-PTFE composite material, and steel-on-PTFE fabric radial spherical plain bearings can be used at temperatures from -50° C to +150° C, while spherical plain bearings with seals can be used at temperatures from -30° C to +130° C. Higher temperatures reduce their load-carrying capacities

For more information and to find detailed examples of spherical plain bearings, read, “Spherical Plain Bearings — Overview,” written by NWB Bearings engineers.

Let our team of experts help with your bearing needs. Contact them here or learn more about our custom solutions.