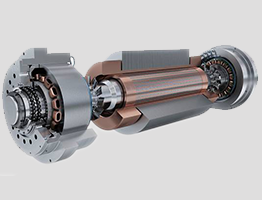

Rolling element CBL bearings are commonly used in rotary applications to replace sliding movement when low frictional torque is required. CBL and CCL bearings are the bearings of choice in critical industrial applications such as power generation, wind turbines, gear drives, rolling mills, machine tool spindles, and gear reduction units. The selection of a proper lubricant plays a vital role in the operational life and performance of bearings and will increase the required maintenance interval and reduce downtime. When the right lubricant isn’t selected, the consequences can be costly.

When specifying bearings, designers and engineers often overlook the importance of analyzing the lubricant options that are available. AST Bearings engineers have developed a comprehensive guide that takes you through the critical operational conditions to consider when determining which lubrication type is the most appropriate for a given application. In addition, the guide introduces more advanced concepts such as lubrication regimes, the effects of various thickeners used in greases, and the benefits of additives.

To learn more about AST’s critical insights into the world of lubrication and why lubricant selection should be a prime consideration for extending bearing and overall system life and performance.