An innovative mid-size company…

Again, seeking to redesign an existing product, a modified setup was applied to a second manufacturer

whose monitor arm was required to hold two monitors with a light at its endpoint. “They had an existing

lighting system in the operating room, and they needed to introduce a brighter light — a fixture with

additional light heads attached,” Fergus said.

Eliminating shadows was paramount, which required the ability to precisely position the arm. But with

the additional lights and weight, the load was too heavy for its existing arm.

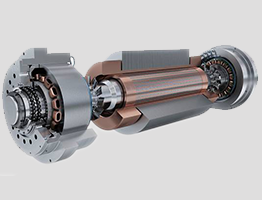

NWB engineers again recommended thin section ball bearings. Its 6700 series assemblies are

exceptionally thin, the ideal configuration for the existing arms and its dimensional constraints (the manufacturer was unwilling to redesign the monitor arm).

Testing, one, two, three

After exhaustive testing for both clients, the thin section bearings proved successful and durable.

“Testing was critical because the healthcare settings required thousands of cycles,” Fergus said. “It’s

extremely expensive to make a service call into a surgical room or hospital.”

Innovative Thinking. Innovative Solution.

NWB offers a complete line of thin section bearings and the engineering expertise to specify and apply

them correctly.

For NWB, it’s not always about steering a client to an existing product; rather, it’s finding a solution that

solves a unique challenge that is the distinguishing NWB value proposition. And it’s this ability and

willingness to assess a problem and consider customer requirements (and limitations) before developing

a solution that distinguishes NWB as an industry leader in ball bearing technology.

NWB has developed a global network of partner manufacturers who will produce customized designs

—unusual in the industry — ensuring the optimal performance of its customers’ products.