Spherical roller bearings heavy duty operations

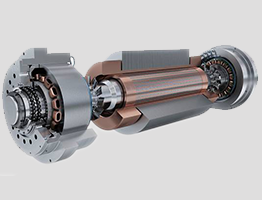

These bearings are used in heavy duty operations.… facing contamination, shock and vibration are constant challenges. Specialty of these bearings adapts as a robust design and higher tolerance for misalignment are especially be fitted to heavy machines, industrial equipment and large gearboxes.

Higher in Performance

The static purpose of heavy industry is to find roller bearings that offer greater reliability at higher operating temperatures, loading capacities and speeds. These are bigger and faster machines, and as mining operations grow harder, the importance of bearing performance and durability is increased. The simple purpose for manufacturers is to deliver a class of higher-performing spherical roller bearings that provide greater load-carrying capability, reduced operating temperature and extended service life.

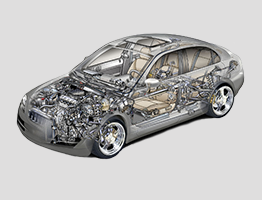

New World Bearings Spherical bearings are used in innumerable industrial applications, where there are heavy loads, moderate speeds and possibly misalignment.

- gearboxes

- wind turbines

- continuous casting machines

- material handling

- pumps

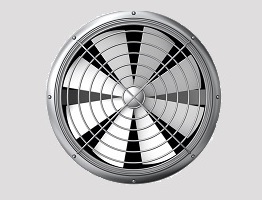

- mechanical fans and blowers

- mining and construction equipment

- pulp and paper processing equipment

- marine propulsion and offshore drilling

- off-road vehicles.

MATERIALS

Bearing rings and rolling elements can be made of a number of different materials, but the most common is “chrome steel”, (High carbon chromium) a material with approximately 1.5% chrome content. Such “chrome steel” has been standardized by a number of authorities, and there are therefore a number of similar materials.

Common materials for bearing cages:

SHEET STEEL (stamped or laser-cut)

POLYAMIDE (injection molded)

BRASS (stamped or machined)

STEEL (machined)

The choice of material is mainly done by the manufacturing volume and method. For large-volume bearings, cages are often of stamped sheet-metal or injection molded polyamide, whereas low volume manufacturers or low volume series often have cages of machined brass or machined steel.

For some specific application, special material for coating (e.g. PTFE coated cylindrical bore for vibratory application) is adopted.